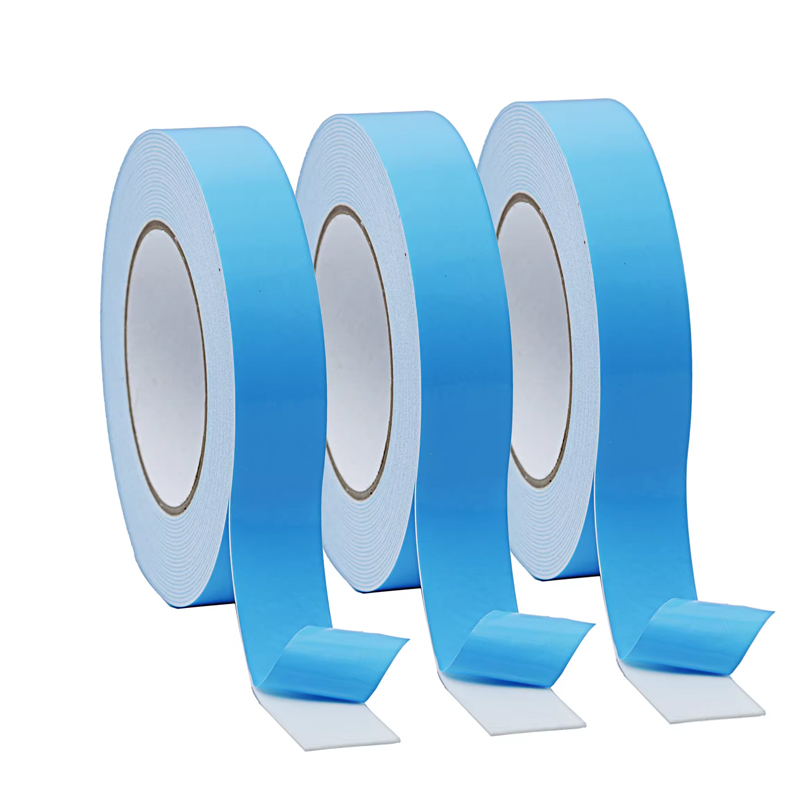

Double Coated Polyethylene (PE) Foam Tape is a versatile adhesive solution widely used across various industries. This guide delves into its features, applications, and provides insights to assist buyers in making informed decisions.

Features of Double Coated Polyethylene Foam Tape

1. Construction and Composition

Double Coated PE Foam Tape consists of a closed-cell polyethylene foam core coated on both sides with pressure-sensitive adhesive. The foam core offers cushioning and conformability, while the adhesives—typically rubber or acrylic—provide strong bonding capabilities.

2. Adhesive Types

Rubber Adhesive: Known for its high initial tack, rubber adhesive bonds well to low surface energy substrates like polyethylene and polypropylene.

Acrylic Adhesive: Offers excellent long-term holding power and resistance to environmental factors, making it suitable for outdoor applications.

3. Thickness and Density

Common thicknesses range from 0.8 mm to 1.6 mm, with foam densities between 65 kg/m³ and 95 kg/m³. These variations allow for flexibility in applications requiring different levels of cushioning and adhesion strength.

4. Temperature Resistance

Double Coated PE Foam Tapes typically operate effectively within a temperature range of -18°C to 82°C, accommodating various environmental conditions.

Applications of Double Coated Polyethylene Foam Tape

1. Automotive Industry

Used for mounting emblems, trim, and other components, the tape's conformability ensures a secure bond on irregular surfaces.

2. Construction and Building

Ideal for attaching signs, panels, and decorative elements, providing a clean finish without the need for mechanical fasteners.

3. Electronics

Employed in assembling devices, securing components, and providing vibration damping due to its cushioning properties.

4. Retail Displays

Facilitates the mounting of point-of-purchase displays, nameplates, and signage, offering a strong bond with easy application.

5. General Industrial Use

Applicable in various manufacturing processes for bonding, sealing, and gasketing purposes.

Selection Tips for Buyers

1. Assess Surface Characteristics

Determine the surface energy of the materials to be bonded. For low surface energy substrates, rubber adhesives are preferable, while acrylic adhesives suit high surface energy materials.

2. Consider Environmental Conditions

For applications exposed to outdoor elements or temperature fluctuations, opt for tapes with acrylic adhesives due to their superior resistance to environmental factors.

3. Evaluate Load Requirements

Assess the weight and stress the bond will endure. Thicker tapes with higher foam density provide better load-bearing capacity.

4. Application Method

Ensure proper surface preparation by cleaning and drying the surfaces. Apply firm pressure during installation to achieve optimal adhesion.

5. Review Technical Specifications

Consult the manufacturer's datasheets for detailed information on adhesive strength, temperature resistance, and compatibility with specific materials.

Conclusion

Double Coated Polyethylene Foam Tape offers a reliable and efficient bonding solution across various industries. Understanding its features and applications enables buyers to select the appropriate tape for their specific needs, ensuring durability and performance in their projects.