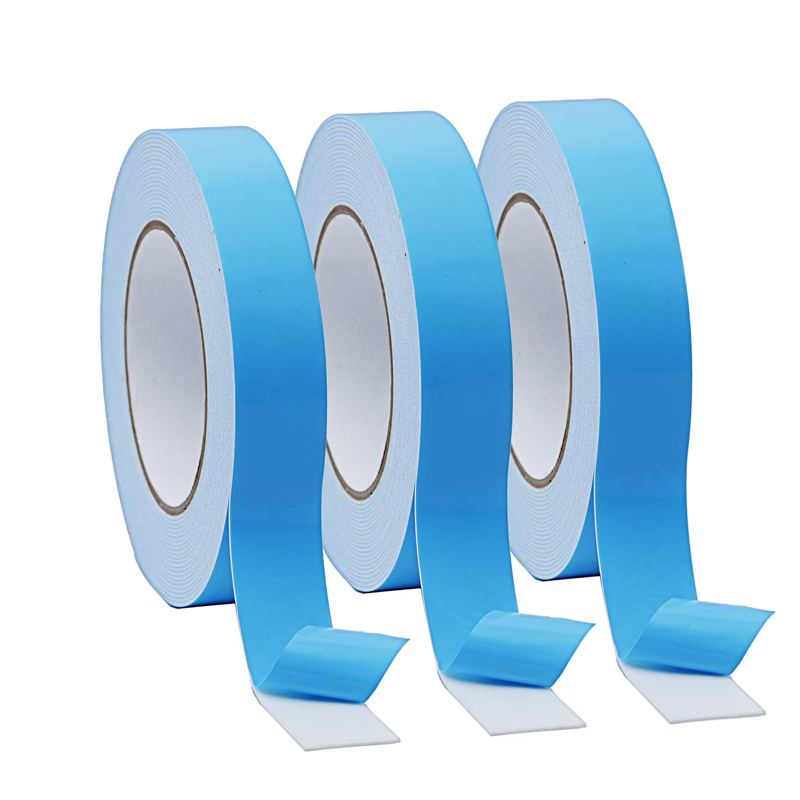

Double Coated Polyethylene Foam Tape

Double Coated Polyethylene Foam Tape is a versatile adhesive solution engineered for strong, long-lasting bonds across a wide range of surfaces. Featuring a closed-cell polyethylene foam core coated on both sides with high-performance pressure-sensitive adhesive (PSA), this tape offers excellent conformability, making it ideal for both smooth and irregular surfaces. Its robust adhesion properties ensure reliable performance in various mounting and bonding applications.

Features

Strong Adhesion: Provides high initial tack and long-term holding power on substrates like metal, glass, plastics, and painted surfaces.

Conformable Foam Core: The closed-cell polyethylene foam adapts to surface irregularities, ensuring a secure bond even on uneven surfaces.

Durable Performance: Resists moisture, UV light, and temperature fluctuations, making it suitable for both indoor and outdoor use.

Easy Application: Available in various widths and thicknesses, with a peel-away liner for quick and clean installation.

Technical Specifications

Foam Carrier: Closed-cell polyethylene

Adhesive Type: Acrylic or rubber-based PSA

Thickness Options: 0.5 mm to 3.0 mm

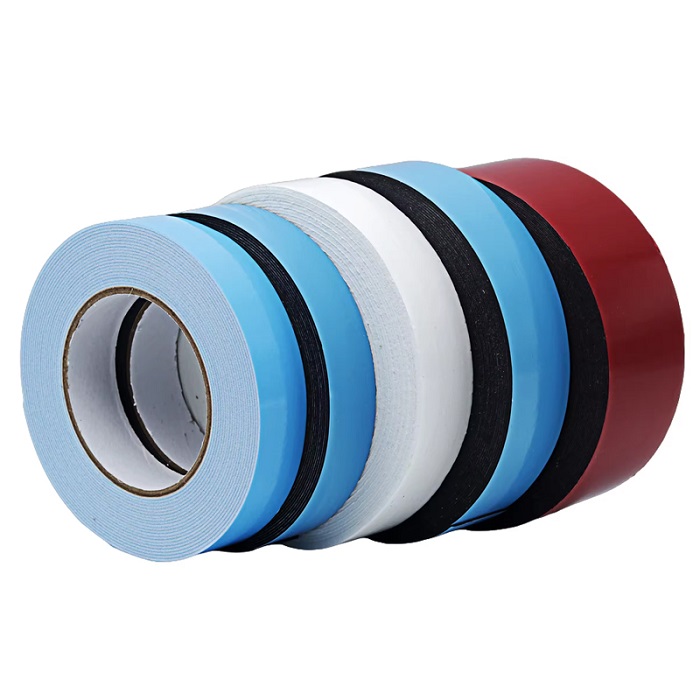

Color Options: White, black, or gray

Temperature Resistance: -20°C to 120°C (-4°F to 248°F)

Available Formats: Jumbo rolls, log rolls, die-cut pieces, and custom sizes

Common Applications

Signage and Nameplates: Securely mount signs, nameplates, and emblems on various surfaces.

Automotive Industry: Attach trims, mirrors, and other components with confidence.

Electronics Assembly: Bond components and panels in electronic devices.

Construction and HVAC: Seal and insulate joints in ducts, panels, and other building materials.

Retail Displays: Mount point-of-purchase displays and promotional materials.

FAQ

Q1: What is Double Coated Polyethylene Foam Tape?

Double Coated Polyethylene Foam Tape is a pressure-sensitive adhesive tape featuring a closed-cell polyethylene foam core coated on both sides with adhesive. It is designed for mounting, bonding, and sealing applications across various surfaces.

Q2: What are the primary applications of this tape?

This tape is commonly used for:

Mounting signs, nameplates, and decorative trims

Attaching mirrors and panels in automotive and construction industries

Bonding electronic components

Sealing doors and windows

Vibration and sound dampening in machinery

Q3: Is this tape suitable for outdoor use?

Yes, certain variants of Double Coated Polyethylene Foam Tape are designed for outdoor applications. They feature a durable foam carrier with excellent resistance to UV light and environmental conditions.

Q4: How does the tape perform on irregular or low surface energy (LSE) materials?

The conformable nature of the polyethylene foam core allows the tape to bond effectively to irregular surfaces. Additionally, specific formulations with rubber-based adhesives provide strong adhesion to LSE materials like polypropylene and polyethylene.

Q5: What are the available thickness options?

Common thicknesses range from 0.8 mm (31 mil) to 3.0 mm, catering to various application requirements.